| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : Bloom

Model Number : BLM

Certification : ISO 9001

Place of Origin : Jiangsu,China

MOQ : 1pc

Price : Negetation

Payment Terms : T/T

Supply Ability : 1000mm/month

Delivery Time : 30 to 45 days

Packaging Details : Packing in wooden case

Material : 38CrMoAlA,42CrMo,9Cr18MoV

Application Field : Household,Agriculture,Industry,Building,Auto parts

Applied Polymers : PE,PA,PET,PVC,PC,ABS,PBT,PEEK,Teflon

Screw Treatment : Nitrided,Bimetallic,PTA,HOVF,Tool steel,HSS,PM Steel

Reinforced Additives : Less than 65% Glass Fibre

Hardness : 58-64HRC

Extruder Screw Barrel And Spare Parts For Coperion Twin Screw Extruder

Bimetallic Screw Barrel For LDPE / HDPE / PP / PE / PVC Blowing Molding Machine

1 . Description

We are the manufacturer of supplier of screw and barrel in china,including designing,manufacturing and sales for these products,we can make any specification of extruder screw barrel and injection molding screw barrel for Engle,Nigrobossi,KMD,NPM,BOY,Haitian,Demag,HUSKY, Nippon Steel, Toshiba, Nissei,Mitsubishi and etc. We also can supply all types of screw and barrel according to your different requirements.

Screw diameter:Φ15mm-Φ360mmL/D=15-56

Length of screw and barrel/cylinder:8000mm

According to different material and plastic products to design different screw structure ,compress rate and L/D.

According to different material and plastic products to design different Barrel with exhaust system and IKV force load system.

| Color | Bright |

| Standard | ISO 9001 |

| Grade | Type 20 / 30 / 35 / 36 /40 /50 / 52 / 53 / 58 / 60 / 65 / 75 / 85 / 92 / 95 / 110 / 125 /135 |

| Brand | Bloom |

| Quality | High wear - resistance adn corrosion resistance |

| Used | For twin screw extruder |

The cross-sectional area is changed by adjusting the flight lead and thread depth, effectively eliminating sudden cross-sectional deformation and impeding resin pooling and extrusion fluctuations. Our (Barrier Mixer) with its high rolling and chaos effects can be mounted on the barrier outlet and screw tip to further enhance kneading and output rate.

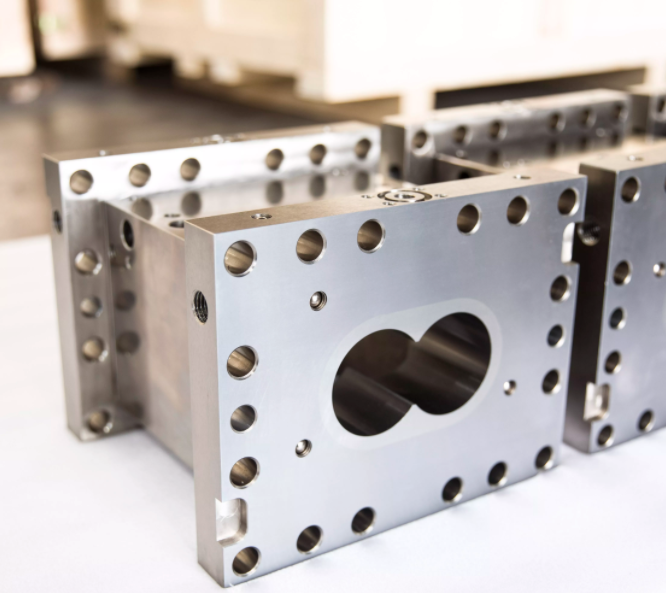

2 . Standard Barrel Parameter Table (selection table)

| Standard Barrel Parameter Table (selection table) | |||

| Model | Size(mm) W.H.L | Hole Diameter(mm) | Center Distance(mm) |

| BLM-20 | 115.105.132 | Φ23 | 18.4 |

| BLM-30 | 135.115.120 | Φ30.6 | 26 |

| BLM-35 | 140.120.140 | Φ36 | 30 |

| BLM-36 | 160.140.150 | Φ36 | 30 |

| BLM-40 | 175.145.160 | Φ41.6 | 34.5 |

| BLM-50 | 190.150.190 | Φ51 | 42 |

| BLM-52 | 200.155.210 | Φ52 | 43 |

| BLM-53 | 210.160.220 | Φ53.3 | 48 |

| BLM-58 | 220.175.240 | Φ58 | 48 |

| BLM-60 | 210.170.240 | Φ60 | 52 |

| BLM-65 | 210.170.240 | Φ63 | 52 |

| BLM-75 | 260.200.290 | Φ71.8 | 60 |

| BLM-85 | 280.215.320 | Φ81.9 | 67.8 |

| BLM-92 | 310.240.360 | Φ92 | 78 |

| BLM-95 | 310.240.360 | Φ94 | 78 |

| BLM-110 | 330.240.420 | Φ109 | 91.5 |

| BLM-125 | 390.290.500 | Φ125 | 98 |

| BLM-135 | 370.300.410 | Φ134 | 110 |

3 . Barrel materials:

We choose different kinds of materials for barrel according to different application.

Normally,there are two main kinds of materials,one is HIP powder tool steel,and the other is domestic steel.

Solid Barrel

| Material Grand | Equivalent steels for | Remarks |

| BLOOM 01 | 45 | Slight |

| BLOOM 02 | 42CrMo | Medium |

| BLOOM 03 | 38CrMoAIa | Strong |

Barrel with installed liner

* made of PM-HIP solid *WR13

By working closely with customers in choosing optional materials,we can minimize wear and tear and associated costs.

| Material Grand | (HRC) Hardness | Application |

| BLM Ni 01 | 55-58 | Wear resistance |

| BLM C02 | 60-62 | Wear + corrosion |

| BLM 01 | 60-62 | Wear resiatance |

| BLM 02 | 60-62 | Wear resistance |

| BLM 03 | 60-62 | Wear resistance |

| BLM 04 | 59-61 | Wear resistance |

3 . Material & Processes of screw barrel for plastic extruder

Alloy-steel of High-quality

1)38CrMoAlA

2)42CrMo

3)9Cr18MoV

4)CW6Mo5Cr4V2

5)Quality Duplex Stainless Steels

6)GH 113

7)Quality Powder Metallurgy Raw Materials

8)Cold/Thermal Spray Hard Metal process

9)Advanced nitriding Process

10)Corrosion & Abrasion Resistance Bimetal Spraying Process

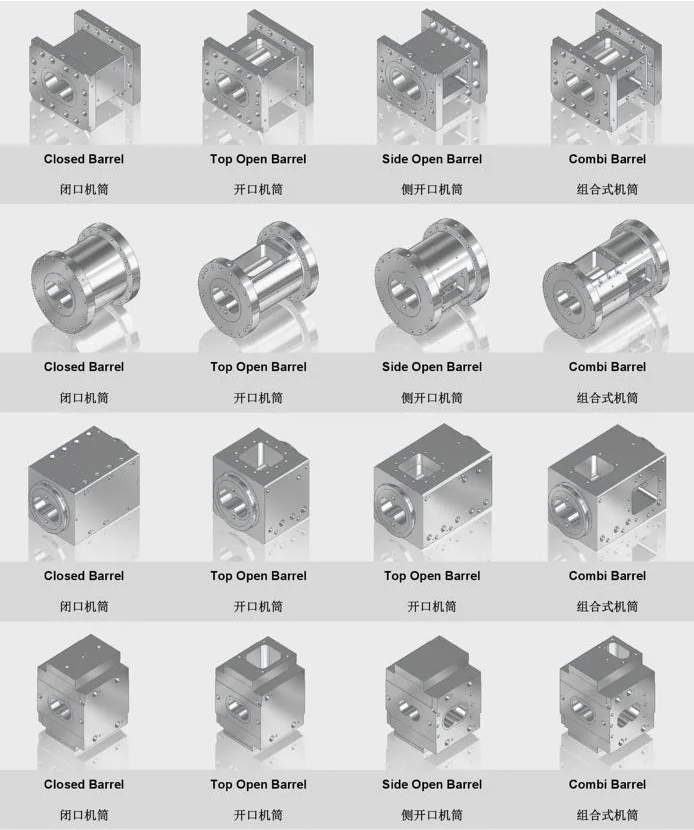

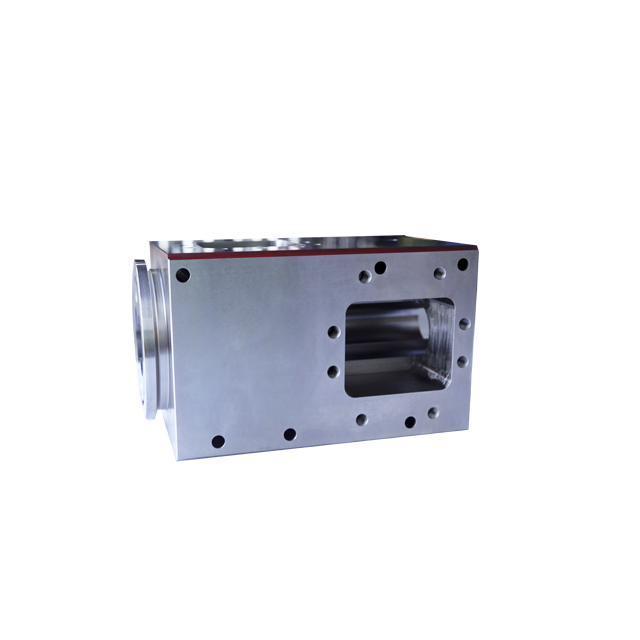

4 . Types

Convey Screw Segment

Mixing Screw Segment

Kneading Block Disk

Transition Screw Element

Deep groove transfer element

Screw element for side feeder

1flighted 2flighted flighted screw elements

5 . As per customer's demand,we can also supply below:

PVC/PE Film Blowing Screw;

Blow Molding Screw;

PS/PE/PP/ABS Sheet Extrusion Screw;

PE Aluminum Plate;

PPR Pipe Screw;

EVA Extrusion Screw;

HDPE High efficiency Screw;

PET Straps Screw;

XPS/EPE Foamed Screw;

Granulation Screw,Vented single screw etc.

|

|

Extruder Screw Barrel And Spare Parts For Coperion Twin Screw Extruder Images |